In daily use, semi-trailers often encounter some common problems, which may cause inconvenience to your transportation work and production plans. Therefore, today we will continue the previous chapter to share solutions to some common problems, hoping to help you better maintain and manage your semi-trailers.

Problem 4: Electrical system failure

The electrical system of a semi-trailer is one of the key elements to ensure the safe operation of the vehicle on the road. This system includes important components such as lighting, signals, and brake lights, which not only enable drivers to see the road clearly and communicate effectively with other vehicles, but also ensure driving safety. If there is a problem with a semitrailer’s electrical system, it can cause serious safety hazards, so maintaining and inspecting the electrical system is crucial.

The following are the impacts and responses to semi-trailer electrical system failures:

Faulty fuses and wire connections: One of the common causes of electrical system problems is a blown fuse or a bad wire connection. This may cause lighting, signal or brake lights to not function properly.

Solution: When you discover an electrical problem, first check the fuse box to make sure all fuses are intact. Also, check the wire connections to make sure they are tight and not loose or oxidized. Many electrical problems can be solved quickly by replacing blown fuses and repairing bad wire connections.

Battery failure: The battery is one of the key components of the semi-trailer’s electrical system. It provides starting energy and stable power supply. The generator is responsible for charging to keep the battery in good condition.

Solution: Regularly check the status of your battery, including voltage levels and terminal cleanliness. If the battery voltage is below recommended levels or the terminals are severely corroded, the battery should be replaced immediately. Also, check the performance of the generator to make sure it is charging properly. When problems are discovered, repair or replace the generator to ensure the battery is always in good condition.

Regular maintenance: Regular maintenance of electrical systems is very important. This includes checking all lighting and signaling equipment to ensure they are working properly. Also, clean and maintain electrical connections to prevent oxidation and corrosion. Develop a regular maintenance schedule that includes inspections of electrical systems. Regular maintenance can help detect problems early and prevent electrical system failures from becoming emergencies.

The driver plays an important role in ensuring the proper operation of the electrical system. They should check all lighting and signaling equipment before each departure to ensure they are working properly. Additionally, if drivers notice any electrical issues while driving, they should take immediate action and seek repair help if necessary.

Problems with a semitrailer’s electrical system can have a significant impact on driving safety. Maintaining and inspecting electrical systems are key measures to ensure the safety of drivers and other road users. Regularly checking the status of fuses, wiring connections, batteries, and generators, as well as performing scheduled maintenance, can help prevent electrical system failures and increase the reliability and safety of your semitrailer.

Question 5: Connection issues such as tow pins and tow hooks

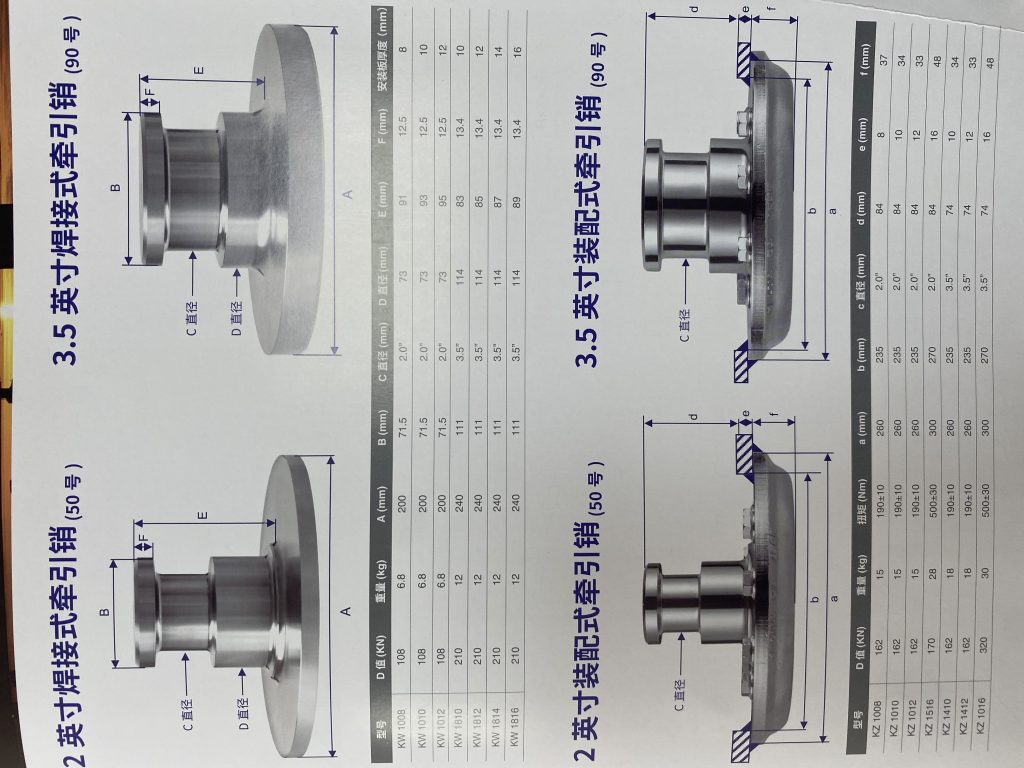

The traction pin is the main physical connection point between the semi-trailer and the tractor. These components bear huge tension and pressure. They are not only responsible for transmitting traction, but also ensuring that the semi-trailer follows the tractor stably while driving. Therefore, their reliability directly affects road safety and transportation efficiency.

Regular inspection: tow pin and connecting parts, including tow hook itself, tow pin, pin hole, etc. Make sure they have no cracks, wear or other damage. If problems are discovered, damaged parts should be repaired or replaced immediately. Regularly inspect the original tow pins and pin holes to make sure they are not deformed, loose or worn. If problems are found, immediate measures should be taken to repair or replace the pin holes to ensure the reliability of the connection.

Regular lubrication: Because the tow hook and connecting parts are subject to a lot of force and friction, lubrication is critical to reducing wear and extending their life. Use an appropriate lubricant and lubricate the tow hook and connecting parts regularly. This helps reduce friction and prevent premature wear of parts. Before lubrication, be sure to clean the joint to ensure that the lubricant can adequately cover the surface.

Regular maintenance: The tow hook and hitch are one of the critical safety components of a semitrailer, so regular maintenance is crucial. Maintenance not only extends the life of these components but also identifies potential problems early. Develop a regular maintenance schedule that includes inspections of tow hooks and hitches. This ensures they are in optimal working order, reducing potential risks from connection issues.

Problems with semi-trailer tow hooks and connections can have a serious impact on road safety and transportation efficiency. To ensure the reliability of these components, critical parts such as tow hooks, connecting pins and pin holes must be regularly inspected, lubricated and maintained. This will help reduce the risk of accidents that may result from connection problems and ensure the semi-trailer operates safely on the road.

Question 6: Cargo fixing problem

The securing of cargo is a crucial part of semi-trailer transportation. Proper cargo fastening can ensure that the cargo will not move, slide or be damaged during transportation. It can also prevent the semi-trailer from unstable driving and reduce the risk of traffic accidents. Here are tips for dealing with semi-trailer cargo securing issues:

Choose appropriate lashings and supports: The nature and size of the cargo are different, requiring the use of different types and strengths of lashings and supports. The key to cargo securing is choosing the right tools and materials. Before transportation, select appropriate lashings, ropes, supports or clamps based on the nature and size of the cargo. Make sure these tools are strong enough to withstand the forces and vibrations the cargo may cause.

Balance the center of gravity of the cargo: Improper stacking or uneven distribution of cargo may cause the semi-trailer to drive unstable and increase the risk of rollover. Therefore, the balance of the center of gravity of the cargo is crucial. When loading cargo, make sure it is evenly distributed within the bed of the semitrailer. Use supports to prevent cargo from tilting or sliding. If necessary, make the necessary calculations to determine the best way to stack the cargo to ensure a balanced center of gravity.

Binding and inspection: When tying goods, ensure they are firm and even to prevent the straps from loosening or falling off during transportation. Also, regularly check the condition of your straps and supports to make sure they are not loose or damaged. Before transportation begins, carefully tie the goods and ensure that the tension of the tie straps is moderate, not too tight and not too loose. During transportation, the driver should regularly check the lashing status of the goods to prevent unexpected situations.

Training drivers: Driver training in cargo securing is crucial. They need to understand proper securing techniques and know how to select and use straps, supports and other securing tools. Transportation companies should provide necessary training to drivers, including best practices and safety procedures for cargo securing. This will help increase driver awareness, reduce incorrect operations and ensure that goods are effectively secured during transportation.

The problem of cargo fixation is directly related to the safety of semi-trailer transportation and the integrity of the cargo. Proper cargo securing reduces the risk of cargo movement, damage or overturning while improving road safety. Transport companies and drivers should pay attention to cargo securing and take necessary measures to ensure that cargo is properly secured to ensure safe and efficient cargo transportation.